Enabling Smart Manufacturing in the Era of Industry 4.0

In the age of the Industrial Internet of Things (IIoT) and a data-driven economy, manufactureres has face

increased global competition, shorter product cycles and canging customer demands requiring

manufactureres to shift their manufacturing paradigms to Industry 4.0. In the future, a factory has to be

digitally connected to be smart and to improve flexibility, effiency and throughput.

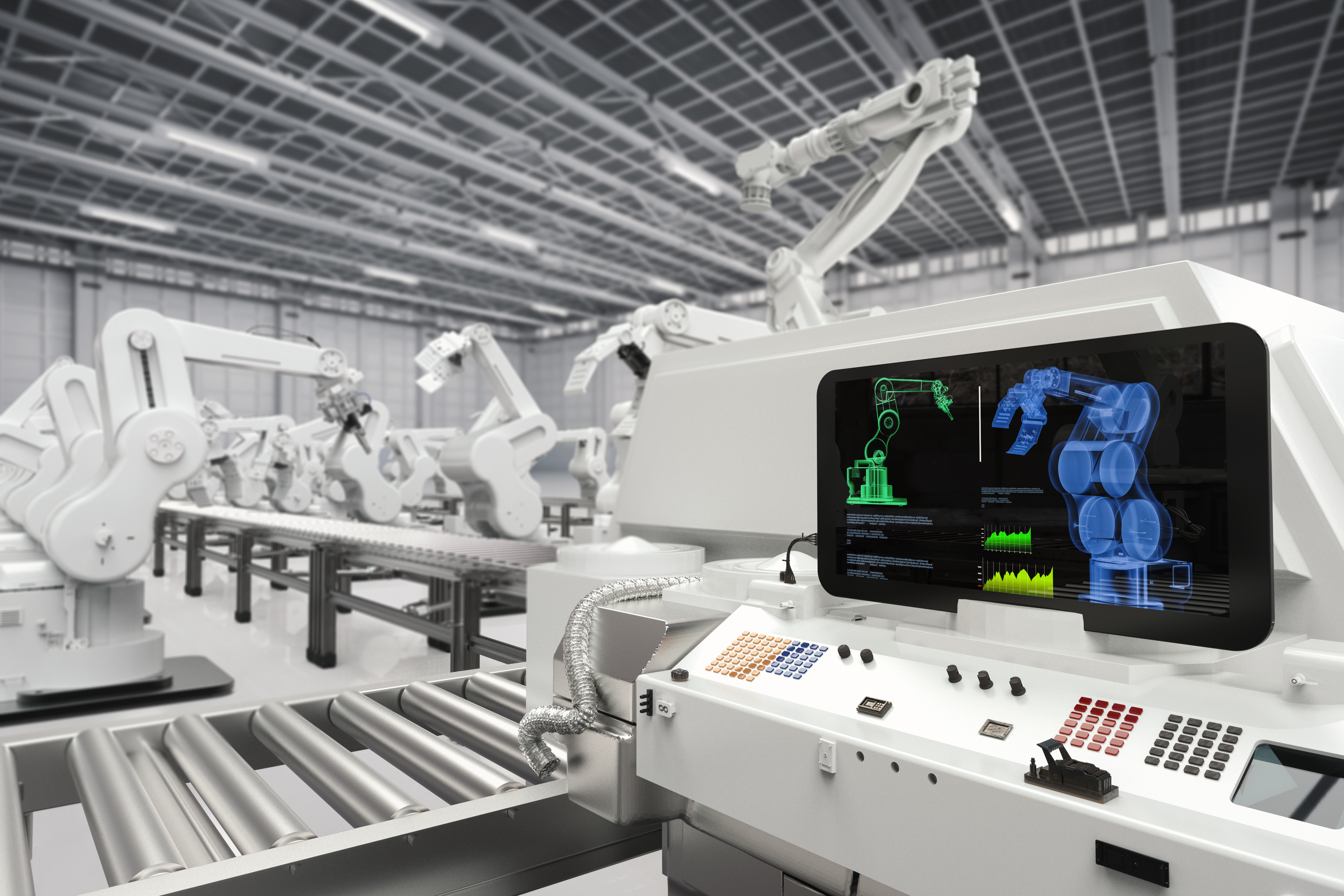

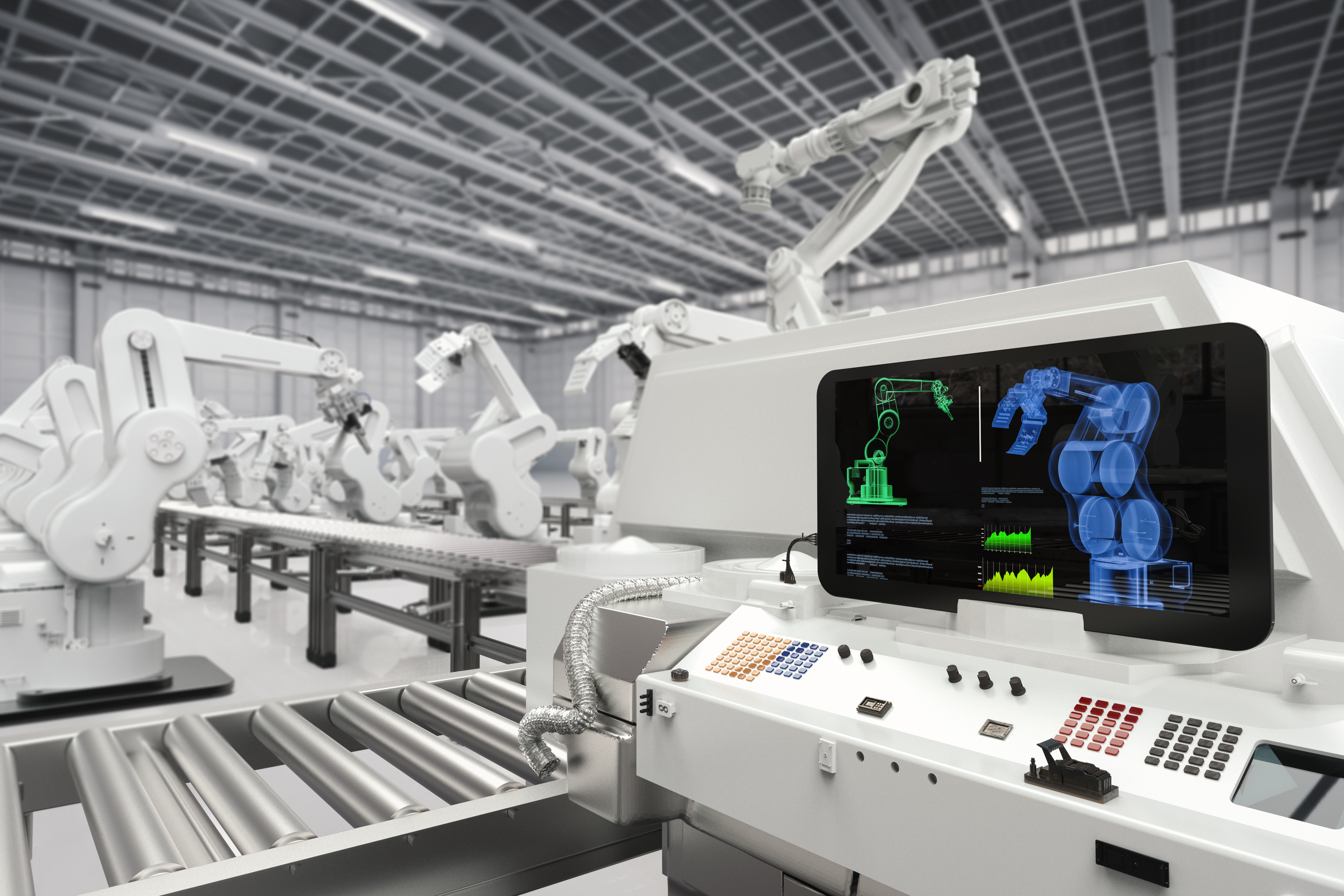

The influx of technological advances over the past few years has impacted the manufacturing landscape tremendously, giving rise to the

phenomenon commonly known as the smart factory. At the heart of the smart factory is data collection, relying heavily on the numerous

snesors, motors and robotics in production and assembly lines.

There is a good reason why the smart factory is being touted as the future of manufacturing. Manufacturers increasingly have to deal with stiff

global competition, shorter product cycles, and changing customer demands, which all add pressure on production schedule, efficiency and

profit margins. To improve flexibillity, effciency and throughput, digital connectivity to enable data collectio is key achieve these goals. In this

article, we focus on three aspects-mass customizaion, predictive maintenance and remote monitoring- to illustrate the benfits of smart

manufactruing for your shop floor.Implementing Mass Customization

More and more modern-day consumers want products that are customized and available on demand, thus driving the shift towards mass

customization in the manufacturing industry. What´s more, mass customization promises custeroms, individually customized products at the price

of mass-produced items. To accomplish mass customization, custom customer orders are intelligently integrated with Enterprise Resource

Planning (ERP) systems or other smart applications, and mapped with the inventry system so upstream materials can be ordered if necessary.

These systems and applications will then connect to the Advanced Planning & Scheduling System (APS) and MES/SCADA systems to initiate

standardization, mass production, custom production and mixed model production

Mass customization is achieved through smart production lines comprised of several heterogeneous smart machines to support both

standardized and customized products. By connecting factory equipment to smart sensors. PLC/edge computer, and the MES shop-foor

equipment can download user/OEM developed programs to execute intelligent procedures according to auomated changeover commands.

This results in minimal breaks in the production process so that business can continue.

Generally speaking the scenario in interconnected factories will entail serial device servers and wired or wireless industrial networking devices

connected to factory equipment to extract data such as product ID. Then networking hardware such as wireless access points and Ethernet

switches are applied to transmit the information over to your MES/DNC (Direct Numerical Control)server. The MES/DNC sends changeover

command and G-Codes over the network to each connected factory machine. This process allows CNC machnies and robots to download

more information to become adaptive smart machines and carry out their jobs effectively.

An adaptive smart machine can perform changeovers on the fly and reconfigure itself with different production modules on the same base

machine platform. It can adapt to constant size and format changes to reduce system downtime and increase production efficiency. By enabling

this adaptive intelligencem production lines remain operational and continue to produce the next order. How ever in a mixes production scenario,

this MES must handle more coordination commands with limited computing capabillity. To alleviate this extra load, edge computers play the

important role of handling the partial decision-making(of the production loop) of the MES. Edge computers reduce the communication latency

and any risks to production stops by autonomously running the entire prodcution processes of the loop in case the MES connection drops off.

Predictive Maintenance and Real-time Monitoring

Self-monitoring is a built-in test(BOT) mechanism that allows machines to perform self-test to discover whether it needs maintenance or repair.

Tyipical tests are for temperature, current voltage, (motor) torque or communication quality, for example the decreased torque output on a

robot arm or overheating/vibration on a CNC motor. Howeber even after identifying potential issues, technician accessibility could be limited and

checking problems on site during operational hours could be costly. Additionally, managers on the enterprise-end of the business need systems

online so they can monitor the operational performance of assets and their availability.

Collecting machine data and connecting systems to the cloud enable remote real-time monitoring an dremote maintenance of your factory and

macnies. With full transparency to machine performance system status and more importantly hard data, mananagers are able to keep track of

current machine performance. Operators can even see historical data on similar machines to predict performances variation outisde the

acceptable boundaries. With this abundance of data, software engineers are able to build a mathematic model based on per-alarm occurrences

to predict machine failure so the operators can proactively schedule maintenance, improving the mean time to repair (MTTR) and saving

significant profit loss from downtime and repair.

Combining this real-time information with remotely connected maintenance software also allows operaors to service machines remotely before

costly isues can occur and with this knowledge they can have the technician scheduled to arrive outisde peak operating hours to avoid

downtime

phenomenon commonly known as the smart factory. At the heart of the smart factory is data collection, relying heavily on the numerous

snesors, motors and robotics in production and assembly lines.

There is a good reason why the smart factory is being touted as the future of manufacturing. Manufacturers increasingly have to deal with stiff

global competition, shorter product cycles, and changing customer demands, which all add pressure on production schedule, efficiency and

profit margins. To improve flexibillity, effciency and throughput, digital connectivity to enable data collectio is key achieve these goals. In this

article, we focus on three aspects-mass customizaion, predictive maintenance and remote monitoring- to illustrate the benfits of smart

manufactruing for your shop floor.Implementing Mass Customization

More and more modern-day consumers want products that are customized and available on demand, thus driving the shift towards mass

customization in the manufacturing industry. What´s more, mass customization promises custeroms, individually customized products at the price

of mass-produced items. To accomplish mass customization, custom customer orders are intelligently integrated with Enterprise Resource

Planning (ERP) systems or other smart applications, and mapped with the inventry system so upstream materials can be ordered if necessary.

These systems and applications will then connect to the Advanced Planning & Scheduling System (APS) and MES/SCADA systems to initiate

standardization, mass production, custom production and mixed model production

Mass customization is achieved through smart production lines comprised of several heterogeneous smart machines to support both

standardized and customized products. By connecting factory equipment to smart sensors. PLC/edge computer, and the MES shop-foor

equipment can download user/OEM developed programs to execute intelligent procedures according to auomated changeover commands.

This results in minimal breaks in the production process so that business can continue.

Generally speaking the scenario in interconnected factories will entail serial device servers and wired or wireless industrial networking devices

connected to factory equipment to extract data such as product ID. Then networking hardware such as wireless access points and Ethernet

switches are applied to transmit the information over to your MES/DNC (Direct Numerical Control)server. The MES/DNC sends changeover

command and G-Codes over the network to each connected factory machine. This process allows CNC machnies and robots to download

more information to become adaptive smart machines and carry out their jobs effectively.

An adaptive smart machine can perform changeovers on the fly and reconfigure itself with different production modules on the same base

machine platform. It can adapt to constant size and format changes to reduce system downtime and increase production efficiency. By enabling

this adaptive intelligencem production lines remain operational and continue to produce the next order. How ever in a mixes production scenario,

this MES must handle more coordination commands with limited computing capabillity. To alleviate this extra load, edge computers play the

important role of handling the partial decision-making(of the production loop) of the MES. Edge computers reduce the communication latency

and any risks to production stops by autonomously running the entire prodcution processes of the loop in case the MES connection drops off.

Predictive Maintenance and Real-time Monitoring

Self-monitoring is a built-in test(BOT) mechanism that allows machines to perform self-test to discover whether it needs maintenance or repair.

Tyipical tests are for temperature, current voltage, (motor) torque or communication quality, for example the decreased torque output on a

robot arm or overheating/vibration on a CNC motor. Howeber even after identifying potential issues, technician accessibility could be limited and

checking problems on site during operational hours could be costly. Additionally, managers on the enterprise-end of the business need systems

online so they can monitor the operational performance of assets and their availability.

Collecting machine data and connecting systems to the cloud enable remote real-time monitoring an dremote maintenance of your factory and

macnies. With full transparency to machine performance system status and more importantly hard data, mananagers are able to keep track of

current machine performance. Operators can even see historical data on similar machines to predict performances variation outisde the

acceptable boundaries. With this abundance of data, software engineers are able to build a mathematic model based on per-alarm occurrences

to predict machine failure so the operators can proactively schedule maintenance, improving the mean time to repair (MTTR) and saving

significant profit loss from downtime and repair.

Combining this real-time information with remotely connected maintenance software also allows operaors to service machines remotely before

costly isues can occur and with this knowledge they can have the technician scheduled to arrive outisde peak operating hours to avoid

downtime